It takes no less than ten steps to manufacture EGIDE bicycle, ski or riding helmets, in leather or technical materials. All these steps are carried out by hand, in Brie-Comte-Robert and Cholet.

Manufacturing

1

Leather selection and processing

The full-grain leathers used for EGIDE helmets are selected from the most renowned tanneries.

They are then mass-treated, guaranteeing unfailing resistance to rain, UV and surface aggression.

2

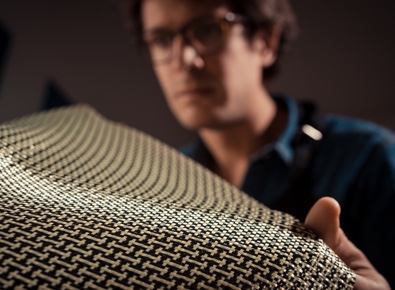

Carbon / Fiberglass: selection and treatment

For technical materials, EGIDE has chosen carbon and fiberglass. Used in the aeronautics industry for high-performance technical parts, these materials guarantee helmet strength, lightness and safety. Their surface is then coated with an anti-scratch varnish.

3

Cut

leathers

The next stage in the manufacturing process: the leathers are cut by hand, to ensure that the leather craftsman is able to locate and select the parts without imperfections.

4

Carbon / Fiberglass: The cut

As with leather, technical materials are cut by hand, this time with a die, according to rigorous draping plans. The craftsman's eye guarantees that the selected pieces are flawless.

5

Leather sewing

Joints and topstitching are made by hand, using a special thread selected for its high resistance to rain, UV and surface abrasion.

6

Gluing and sheathing

Once the surfaces have been prepared, the skullcap is glued and the leather is applied to the skullcap. An inspection is necessary after the drying time.

7

Assembly

The components added at this stage are checked and weighed one by one. The chinstrap and ventilation eyelets are then crimped, the protective foam glued, and the visor fitted.

8

Marking

Hot-stamping of the EGIDE logo on the helmet and chinstrap completes the meticulous finish.

9

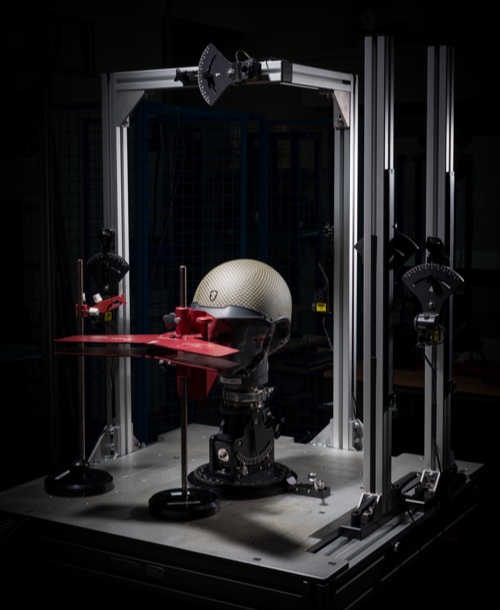

Certification

and compliance monitoring

Once manufactured, each helmet is subject to European standards:

These tests are carried out at extreme temperatures (from -20 to +50°). Random certification follow-up tests are carried out in collaboration with an accredited French laboratory.

10

Control / Shipping

Final step: each helmet is inspected one last time. All helmets are numbered for traceability. Before being carefully packed and delivered with the owner's manual in a protective cloth bag.